Case Study: Pharmaceutical Manufacturing

On-Site Electrochemical Treatment of An Antiparasitic API in Pharmaceutical CIP Rinse Water

Project Highlights

- Major pharmaceutical manufacturer expanding operations in Puerto Rico

- Achieved safe discharge and met treatment objectives

- > 99.9% destruction of antiparasitic API

- Achieved corporate sustainability goals

Challenge

A major pharmaceutical manufacturer in Puerto Rico faced a significant challenge when it planned to begin manufacturing a new product and expected to generate 1.25 million gallons (MG) of clean-in-place (CIP) waste annually with high concentrations of antiparasitic active pharmaceutical ingredients (API) at approximately 4,000 µg/L. The company aimed to treat this waste to below 300 µg/L to ensure safe discharge and meet its internal treatment goals.As a member of the Pharmaceutical Supply Chain Initiative (PSCI), the organization had set a 2030 sustainability goal to reduce or eliminate pharmaceutical discharge into the environment. Despite the lack of local regulations on pharmaceutical ingredients, the company committed globally to treating ecotoxic antiparasitic ingredients before discharge.The organization opted against the conventional approach of off-site disposal, which involves transporting aqueous waste to the mainland USA for incineration. This method, commonly used for aqueous waste disposal, proved unviable due to heightened risks and expenses associated with handling such waste on an island. Consequently, an on-site treatment solution was necessary.

Axine’s on-site system installation

Solution

Axine collaborated with the site to conduct treatability and pilot testing of batch rinse water to validate the performance of Axine’s electrochemical oxidation (EOx) process. The rinse water underwent comprehensive analysis before and after treatment for APIs (active pharmaceutical ingredients), COD (chemical oxygen demand), TOC (total organic carbon), TSS (total suspended solids), TDS (total dissolved solids), and other parameters. Independent lab analysis was conducted using a dedicated method developed for the API in the wastewater matrix.

Axine designed a turnkey, containerized system with upstream ultrafiltration (UF) and reverse osmosis (RO) pre-treatment steps. These steps concentrated the API before entering the electrochemical process and produced a clean permeate stream for discharge. The concentrated wastewater then entered Axine’s EOx system for the oxidative destruction of TOC, COD, and antiparasitic APIs. To simplify facility operations, Axine provided this process through a multi-year Treatment-as-a-Service (TaaS) contract, guaranteeing operating run-time and effluent quality.

Axine’s proprietary EOx process harnessed electricity and advanced catalyst materials to create a potent oxidation effect. Hydroxyl radicals and mixed oxidants were generated, effectively mineralizing soluble organic compounds, including stable APIs or PFAS (per- and polyfluoroalkyl substances), without reliance on specific wastewater conditions.

Results

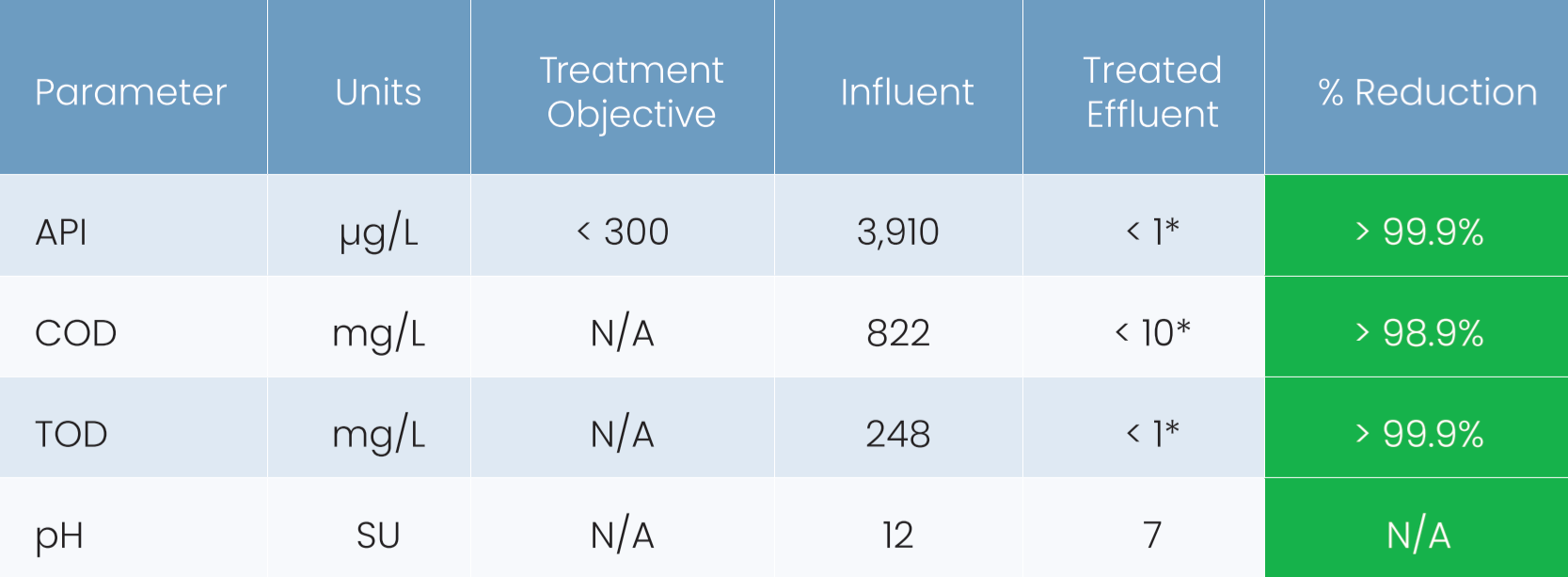

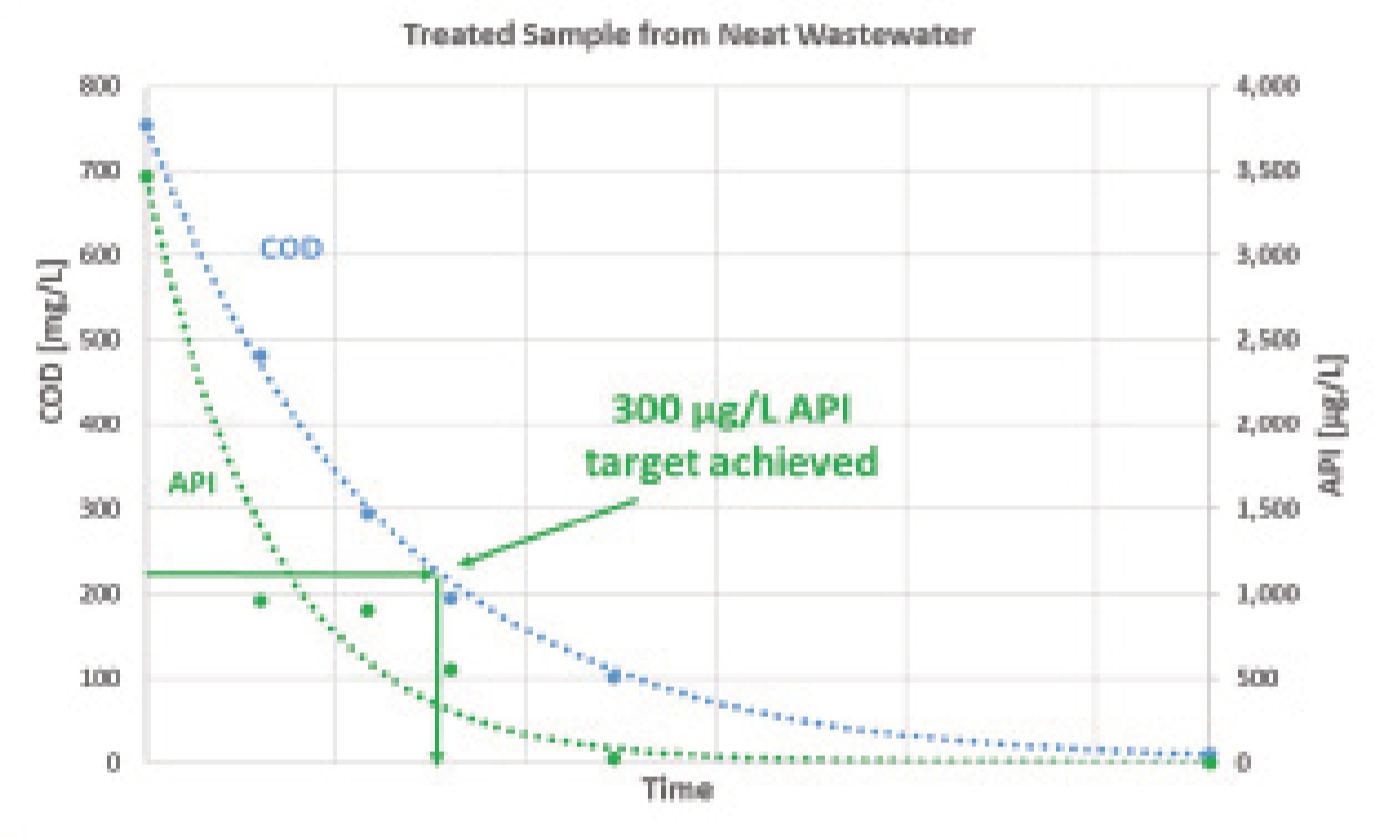

In 2019, Axine delivered and commissioned a full-scale electrochemical oxidation system at the facility. The system has operated continuously, achieving >99.9% destruction of IPA, acetone, and COD in the treated effluent since startup, as shown in Table 1. Under Axine’s Treatment-as-a-Service (TaaS) model, these results were attained without the need for dedicated site personnel and operations. The site’s success in meeting wastewater discharge limits led to the renewal of their service contract with Axine.

Table 1 – Wastewater parameters before and after Axine treatment. *Values indicate the analytical detection limits of these compounds

Figure 1 – Treatment reduction curves for API and COD concentrations before, during and after Axine treatment of an antiparasitic API.

About Axine Water Technologies

Axine Water Technologies is a provider of an innovative industrial wastewater treatment technology that destroys toxic organic contaminants including per- and polyfluoroalkyl substances (PFAS), active pharmaceutical ingredients (APIs), and other emerging contaminants on-site using electrochemical oxidation. With over a decade of treatment experience and more than 100,000 hours of commercial runtime, Axine is helping industrial manufacturers meet discharge permit requirements, eliminate off-site disposal costs and bottlenecks, and reduce litigation risk. Learn more at axinewater.com.