CASE STUDY: PHARMACEUTICAL MANUFACTURING

On-Site Treatment of An Antiparasitic API in CIP Rinse Water to Eliminate Off-Site Disposal

Customer Pain Point

A US pharmaceutical manufacturing plant generates several hundred thousand gallons per year of cleanin-place (CIP) rinse water contaminated with an antiparasitic active pharmaceutical ingredient (API) and organic solvents. The stream was historically trucked off-site for incineration because the API is ecotoxic and cannot be discharged to sewer.

The site experienced periodic disruptions in disposal service, which resulted in production bottlenecks, delays, higher costs and risks. To address this problem, the facility wanted to treat the stream on-site, so the treated water could be safely discharged to sewer. To achieve this objective, the API needed to be reduced from a maximum of 8,000 µg/L to < 66 µg/L.

Several options were considered. Axine was selected and signed a multi-year service agreement with the customer to design, build, own and operate a turnkey, on-site wastewater treatment system to treat and destroy APIs in the rinse water to meet the treatment objective. The Axine solution not only eliminates bottlenecks and reduces site opex, it also provides the site with the operational flexibility to treat rinse water from future expansion.

Axine treatment system operating at customer site.

Test Methodology

Before entering into a service agreement, Axine and the site conducted treatability tests to verify the performance and cost of Axine’s solution. Samples of rinse water were shipped to Axine for testing. The rinse water was analyzed before and after treatment for the target API, COD, TOC, TSS, TDS and other parameters. The local municipality also conducted Whole Effluent Toxicity (WET) testing on the Axine treated water to verify that Axine had achieved a sufficient reduction in toxicity required for safe discharge.

Axine Treatment Results

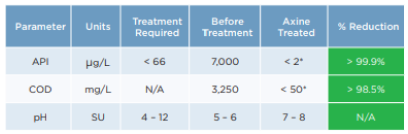

Multiple tests verified that Axine successfully oxidized and destroyed the API to < 2 µg/L, which is below the detection limit for this API and below the site requirement of < 66 µg/L for discharge to sewer. Table 1 shows the concentration of API and COD before and after treatment by Axine for one example test. The API was reduced by > 99.9% from 7,000 µg/L to < 2 µg/L and the COD was reduced by > 98.5% from 3,250 mg/L to < 50 mg/L.

Table 1 – Wastewater parameters before and after Axine treatment. *Values indicate the analytical detection limits of these compounds

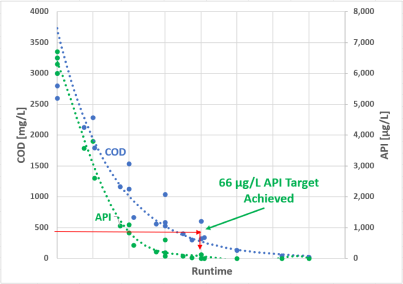

Figure 1 – Treatment reduction curves for API and COD concentrations before, during and after Axine treatment of an antimicrobial API

System Design & Operation

Axine’s turnkey, containerized treatment system for this application includes wastewater receiving tanks, electrochemical reactors, power supply, controls and instrumentation, trace by-product gas management and flow management systems. Axine’s services include 24×7 remote system monitoring, routine and preventative maintenance, all consumables and replacement parts, rapid-response field service support, on-line system monitoring and monthly KPI reporting. Proprietary data analytics monitors a wide range of performance metrics to enable safe and reliable operation.

Figure 1 – Treatment reduction curves for API and COD concentrations before, during and after Axine treatment of an antimicrobial API