“PFAS is one of the most serious health and environmental challenges facing the water sector. For industrial, municipal, or federal facilities required to treat PFAS contaminated water and wastewater, we believe PFAS destruction should be the required standard for safe, sustainable management of PFAS contaminated water.” — Greg Peet, CEO of Axine Water TechnologiesThe Vancouver clean tech company, Axine Water Technologies, which is driving to ZERO in pharmamanufacturing wastewater has now adapted their proprietary EOx technology for the on-site destruction of PFAS, an emerging contaminant of concern.

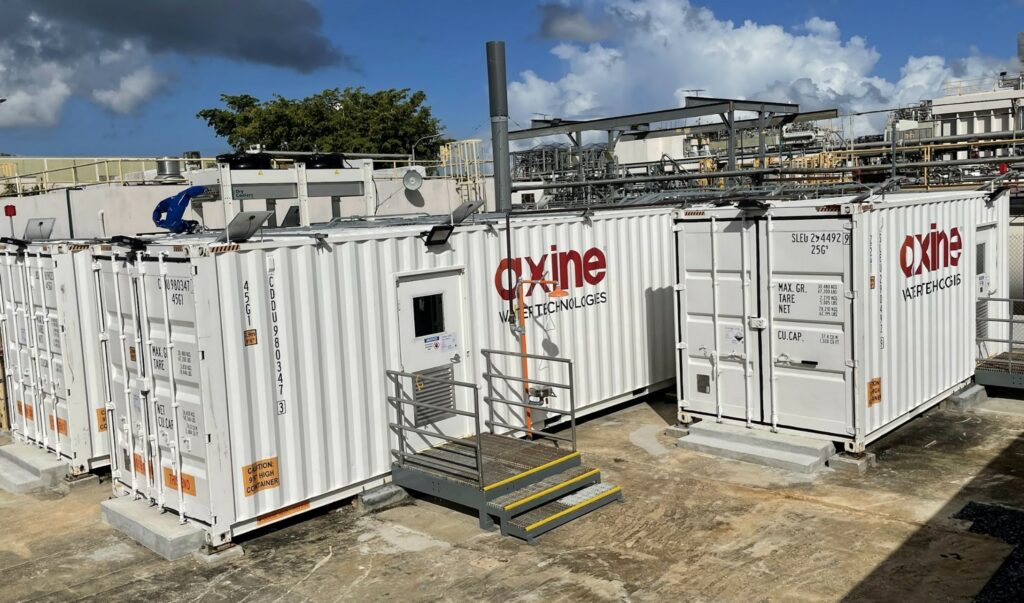

Axine’s on-site solutions treat wastewater and aqueous waste in a wide range of applications including pharmaceutical manufacturing, and now PFAS destruction. Designed and built off-site the treatment systems are modular and versatile. Wirelessly connected and remotely monitored there is no need for operators. Image Courtesy AxinePer-and polyfluoroalkyl substances (PFAS), commonly referred to as “forever chemicals”, have been manufactured and used in a wide range of industries worldwide since the 1940s.

PFAS chemicals are very persistent in the environment and in the human body and may lead to adverse health outcomes in humans, including reproductive and developmental, liver, kidney and immunological effects

WATERTODAY reached out to Axine’s CEO, Greg Peet, to learn more about the Axine system that destroys PFAS – as opposed to removal by other alternative systems that simply collect PFAS for hazardous disposal or secondary removal.

WT: Briefly explain the EOx Technology for our viewers.

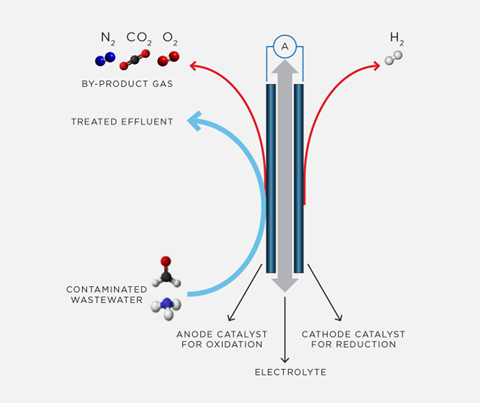

Peet: Axine’s electrochemical oxidation (EOx) technology applies electricity to advanced catalysts to generate mixed oxidants. PFAS compounds are oxidized and mineralized to trace by-product gases such as H2, O2, N2, CO and CO2.

Axine’s technology applies electricity to solid state electrodes made from advanced catalyst material. Wastewater or aqueous waste flows through the reactor. Power is applied to electrodes and the process mineralizes and destroys all types of toxic, recalcitrant organics through multiple oxidation mechanisms.

There is no use of hazardous chemicals, and no solid or liquid waste is produced.

WT: Which PFAS compounds are you able to treat?

Peet: We can treat the most widely used compounds, PFOA and PFAS, as well as all the related shorter chain compounds.

The wastewater we tested contained PFOA, PFOS, PFHpA, PFHxA, and PFBA.

We were able to achieve a 5-log reduction (99,999%) to below detection levels of all these compounds as well as their oxidation byproducts.

WT: Any pilot projects on the go?

Peet: Axine has several lab pilot systems utilizing commercial scale reactors treating PFAS at its development facility in Vancouver, B.C. Design and construction of containerized PFAS field pilot systems is underway with plans to deploy worldwide in early 2023.

WT: What’s next?

Peet: We’re taking our proven electrochemical oxidation technology which has been deployed in multiple Fortune 500 pharmaceutical plants to remove APIs and apply it to the PFAS market.

On August 26, 2022, the US federal government Environmental Protection Agency (EPA) announced that it will designate the two most common PFAS compounds (PFOA and PFOS) as hazardous substances under the Superfund law. The Environmental Working Group, an environmental organization, last year identified 41,828 industrial and municipal sites in the United States that it said are known or suspected of still using PFAS.

Axine will leverage its proprietary electrochemical oxidation (EOx) technology commercially deployed for pharmaceuticals to provide a cost-effective solution to certify the destruction of PFAS compounds to meet evolving regulatory standards.

By Suzanne Forcese

WATERTODAY