Case Study: Metal Finishing Industry

Achieving Complete Destruction of PFAS Using electraCLEAR™ Process

Project Highlights

• Pilot trial at Lacks Enterprises Inc.

• Seamless integration with an existing consolidating and concentrating process

• 99.99% (or >99.99%) destruction of long an short-chain PFAS

• Planned implementation of destruction systems at multiple sites

Challenge

Manufacturing facilities have historically been mandated to use per- and poly-fluoroalkyl substances (PFAS) in their operations. With recent tightening EPA and state regulations, manufacturers need cost-effective methods to capture and destroy legacy PFAS in wastewater, groundwater, and stormwater discharges. This need is critical as many publicly owned treatment works (POTWs) now refuse to accept waste streams containing such contaminants.

In early 2023, Lacks Enterprises Inc., a large automotive component supplier in the midwestern US, engaged Axine to address destruction of legacy PFAS compounds in wastewater from its manufacturing processes. Recognizing the potential impact of pending regulation, the Lacks team had already begun capturing and concentrating PFAS using the foam fractionation process developed and implemented on-site. To mitigate long-term risks and costs associated with offsite disposal, the site sought on-site destruction solutions and identified Axine’s electraCLEAR™ technology for its safety and cost benefits over competing destruction alternatives.

Approach

Axine initiated the project with a laboratory-scale test of the electraCLEAR process on a 10 gallon sample of concentrated wastewater containing 69,900-82,900 ppb of various PFAS and precursor compounds. Laboratory-scale experiments showed >99.99% destruction of total detectable PFAS to below

analytical detection limits using several different electrode combinations. Encouraged by these results, the Lacks engineering team proceeded with pilot-scale testing at one of its manufacturing sites in west Michigan. In early 2024, Axine

delivered a fully containerized electraCLEAR pilot unit to simplify testing, which could easily run parallel to the existing wastewater treatment process. Concentrated waste was collected in 325-gallon totes for the electrochemical destruction process, allowing independent optimization of both systems.

Testing was conducted in two phases to evaluate and optimize the benefits of various electrode combinations. Samples were collected at regular intervals and analyzed using US EPA Methods 533 and 537.1, including Total Organic Precursors (TOP) analysis for PFAS and precursor compounds. The testing phases were separated by a week to allow for complete laboratory analysis of the first phase results.

Results

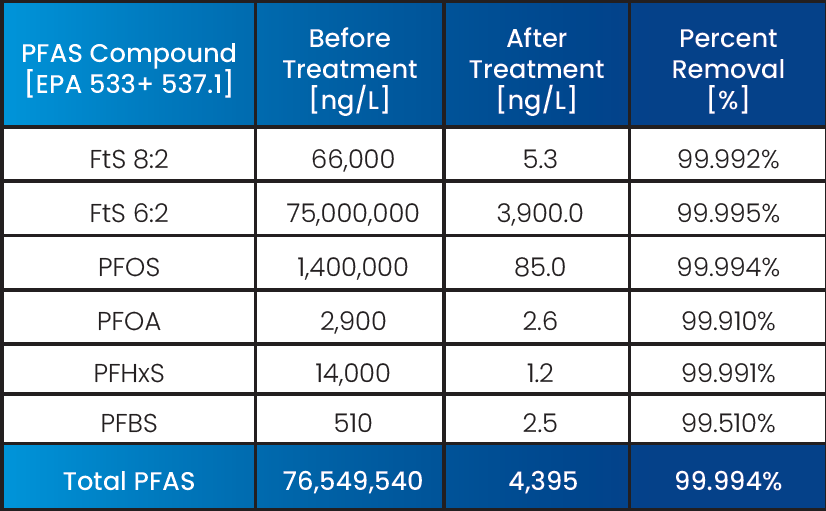

Pilot testing of Axine’s electraCLEAR process demonstrated 99.9%-99.999% destruction of all PFAS and precursor compounds in the concentrated foamate. TOP analysis showed no substantial precursors remaining in the treated water.

Based on these successful results, Lacks Enterprises Inc. elected to move forward with the full-scale design of PFAS concentration and electraCLEAR destruction systems at multiple sites in its manufacturing operations. The first new projects will come online in late 2024, with several additional systems to be installed in mid to late 2025.

Table 1 – Treatment results of EPA regulated PFAS molecules.