Industrial manufacturing operations in virtually every market generate wastewaters contaminated with toxic, non-biodegradable organic pollutants, which are difficult and expensive to treat, subject to tough regulations and pose health risks to communities and the environment.

Axine Water Technologies, located in Vancouver, British Columbia, has developed a cost-effective, on-site solution utilizing electrochemical technology for treating high concentrations of organic active ingredients, solvents, surfactants, polymers, pesticides, aromatics, other complex organics, nitrogen and ammonia.

Organic laden waste streams generated by pharmaceutical, electronics and chemical manufacturing as well as crop protection, coating and other specialty chemical manufacturers can be treated on-site.

BREAKTHROUGH TECHNOLOGY

Axine’s electrochemical technology utilizes advanced catalyst materials and electricity to oxidize and break down pollutants into harmless byproduct gases such as nitrogen, oxygen and hydrogen. Using a system that is smart, modular and scalable, these electrochemical reactors are packaged into fully- automated, turnkey systems that are seamlessly integrated into existing on-site operations.

Unlike traditional treatment methods, no chemicals are required and no other waste or byproducts are generated. As a result, wastewater can be safely discharged to the sewer. Or, it may be reused, which is an option more industrial plants are adopting in the emerging trend towards “smart factories” characterized by automation, adaptability and low impact manufacturing.

SOLUTIONS TO INDUSTRIAL ISSUES

In many cases, wastewater streams generated by industrial facilities cannot be treated on-site with conventional technology and must be trucked off-site. While trucking and disposal is a widespread practice, it is expensive, high risk and can cause operational bottlenecks and safety issues. On-site treatment results in immediate cost savings, reduced risks, streamlined operations and improved safety and environmental performance.

In addition, wastewater streams generated by industrial facilities are often contaminated with toxic organic pollutants which exceed discharge limits. This can lead to fines, production bottlenecks and even curtailment. Axine systems ensure that wastewater is treated to specified objectives. All discharge permit levels are met with 24/7 remote monitoring, data analytics and reporting, as well as on-site field service and end-to-end maintenance to ensure ongoing operations.

A third major issue for some manufacturers is treating active ingredients before they are discharged to the environment. This is a significant emerging issue in the pharmaceutical industry, which is under increasing pressure to eliminate antibiotics and active pharmaceutical ingredients from manufacturing site effluent. This is because antibiotics contribute to the emergence of antibiotic resistant strains of bacteria (often referred to as AMR – antimicrobial resistance) or “superbugs” which are a significant health risk. Axine’s technology can treat active ingredients on-site to eliminate this risk.

SERVICE AGREEMENTS

Axine’s systems can be installed, monitored and maintained on-site under multi-year service agreements. Not only do customers realize hard cost savings, but also soft cost savings such as streamlined operations, improved safety and logistics, reduced environmental liabilities and reputational risks. Application fits are confirmed via a rigorous stage-gated project development approach from initial assessment to commercial deployment.

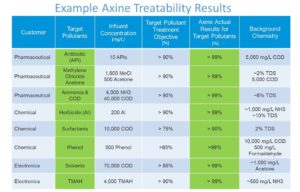

TREATABILITY RESULTS

Axine’s technology can treat a wide range of complex solvents, surfactants, polymers, pesticides, aromatics, pharmaceutical active ingredients and other organics that are typically non-biodegradable. Utilizing its certified in-house chemical laboratory, the company performs treatability tests using samples of problem waste streams.

Axine is developing projects in the pharmaceutical, electronics and chemical manufacturing markets. Future markets may include refineries, upstream oil and gas, waste management, textiles and other heavy industries.

One electronics manufacturing facility generates a wastewater stream contaminated with solvents at a concentration of 70,000 mg/L COD. This wastewater stream could not be safely discharged to the sewer because it exceeded the flash point requirements. For years, this stream was trucked off-site to a remote location and incinerated. Axine designed, built, installed and operates a turnkey treatment system at the customer’s site that reduces COD by 85%, so treated water can be reused on-site in cooling towers.

At a pharmaceutical manufacturing plant, Axine will finance, design, build, install, operate and maintain a turnkey on-site treatment system. The system will treat process water contaminated with solvents and alcohols so that the plant can meet discharge standards.