Case Study: Pharmaceutical Manufacturing

Treating & Reducing IPA and Acetone in Process Wastewater to Meet Local and EPA Permit Requirements

Project Highlights

• Toxicity event triggered a technology change

• Met local and EPA permit requirements

• On-site treatment of IPA

Challenge

A prominent pharmaceutical manufacturer in Northeastern United States sought a wastewater treatment solution to maintain compliance with permitted discharge limits. The facility utilized an isopropyl alcohol-based (IPA) solvent during their reaction vessel wash process, and the conversion of IPA to acetone in wastewater posed an EPA-regulated compliance challenge.

Axine’s on-site system installation

Historically, the customer had relied on biocides to prevent IPA conversion, however a system malfunction resulted in a toxicity event in the discharge to the local publicly owned treatment works (POTW). To ensure compliance with permitted limits, their goal was to reduce IPA concentrations by 90% in their wastewater effluent, keeping acetone discharge concentrations below 20.7 mg/L (daily average) and 8.2 mg/L (monthly average). Furthermore, the treatment system needed to handle IPA peaks and consistently meet these limits.

Solution

Axine partnered with the facility to conduct treatability testing of the site’s rinse water, validating the effectiveness of Axine’s electrochemical oxidation (EOx) process. Samples of rinse water were analyzed for COD (chemical oxygen demand), TOC (total organic carbon), TSS (total suspended solids), TDS (total dissolved solids), and other parameters before and after treatment.

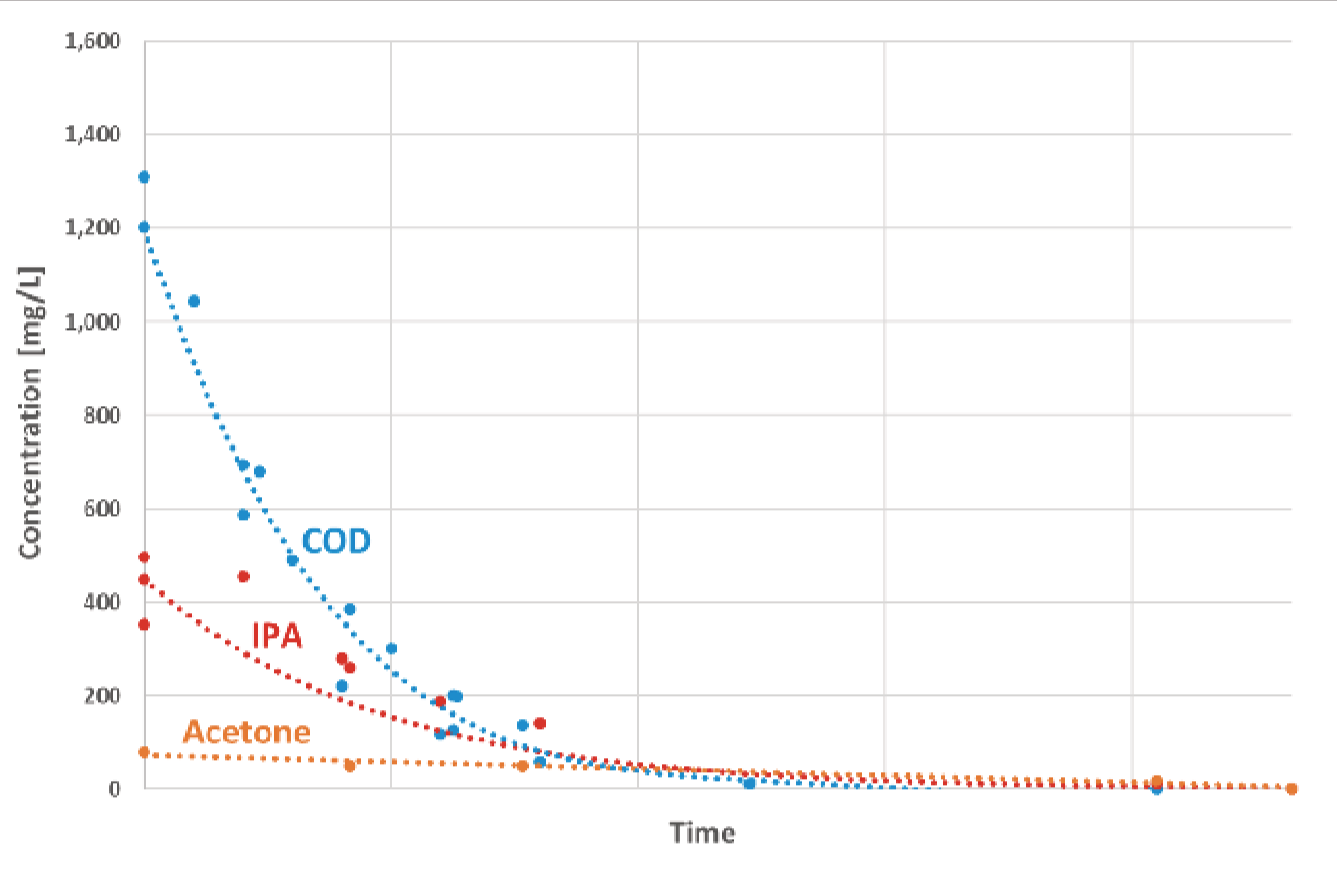

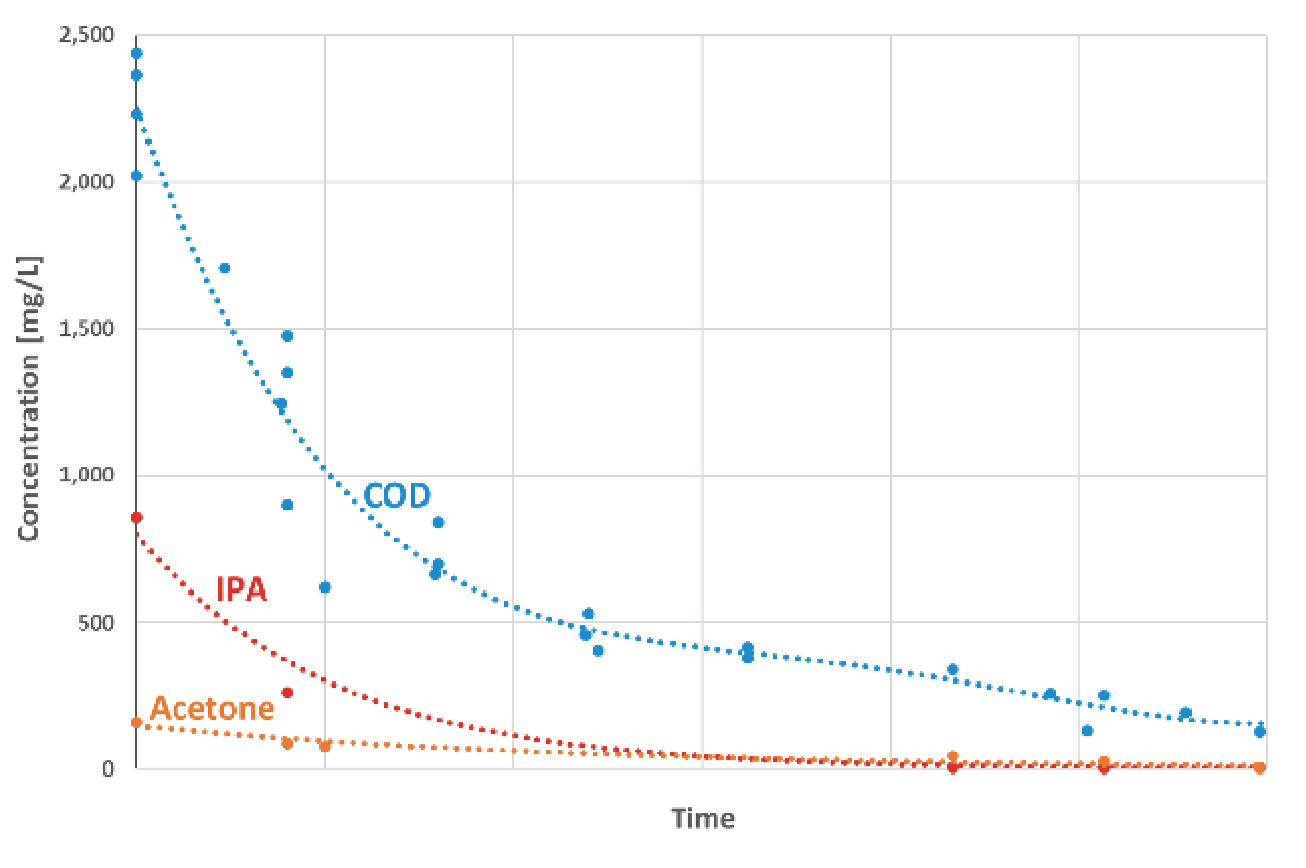

Testing covered raw and spiked wastewater samples, with raw wastewater having 500 mg/L IPA and 75 mg/L acetone concentrations. To simulate IPA peaks, spiked wastewater contained approximately 900 mg/L IPA and 120 mg/L acetone. In both cases, Axine’s process successfully reduced IPA and acetone concentrations to < 1 mg/L, as depicted in Figure 1. Additionally, the process consistently reduced influent COD concentration from approximately 1,300 mg/L to <10 mg/L.

Figure 1 – Baseline wastewater treatment reduction curves for IPA and COD concentrations before, during and after Axine treatment of IPA

Figure 2 – Spiked wastewater treatment reduction curves for IPA and COD concentrations before, during and after Axine treatment of IPA

Results

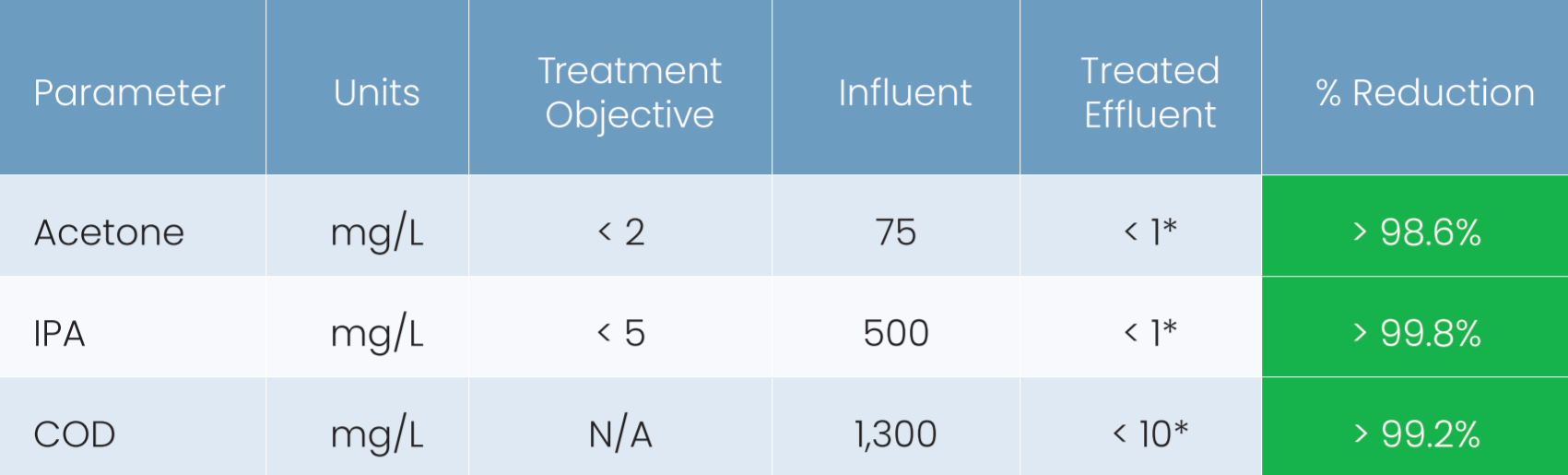

In 2019, Axine delivered and commissioned a full-scale electrochemical oxidation system at the facility. The system has operated continuously, achieving >99.9% destruction of IPA, acetone, and COD in the treated effluent since startup, as shown in Table 1. Under Axine’s Treatment-as-a-Service (TaaS) model, these results were attained without the need for dedicated site personnel and operations. The site’s success in meeting wastewater discharge limits led to the renewal of their service contract with Axine.

Table 1 – Wastewater parameters and treatment results *Values indicate the analytical detection limits of these compounds

About Axine Water Technologies

Axine Water Technologies is a provider of an innovative industrial wastewater treatment technology that destroys toxic organic contaminants including per- and polyfluoroalkyl substances (PFAS), active pharmaceutical ingredients (APIs), and other emerging contaminants on-site using electrochemical oxidation. With over a decade of treatment experience and more than 100,000 hours of commercial runtime, Axine is helping industrial manufacturers meet discharge permit requirements, eliminate off-site disposal costs and bottlenecks, and reduce litigation risk. Learn more at axinewater.com.